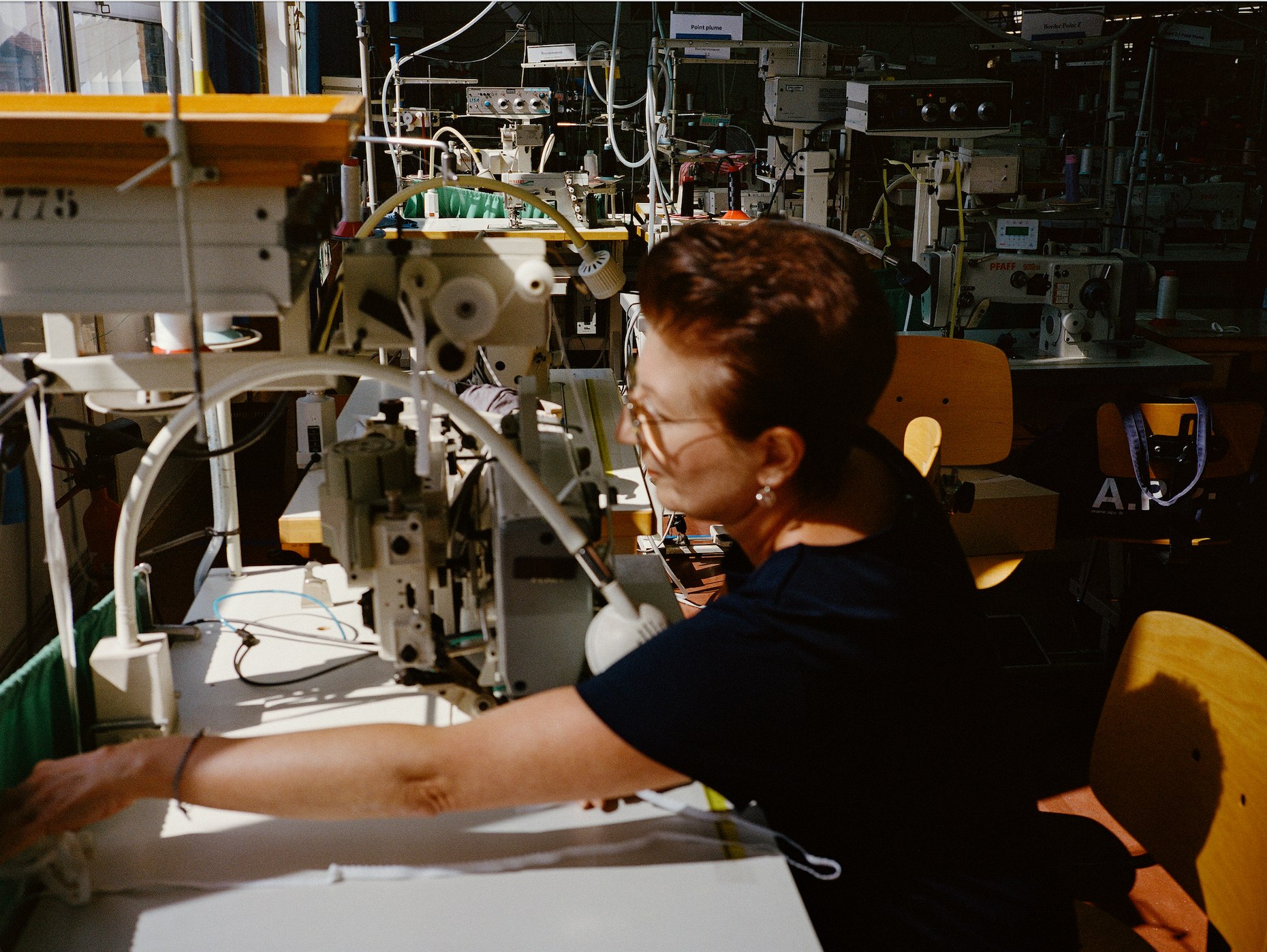

For almost two years we searched for the perfect workshop to meet our ecological, technical and aesthetic requirements. It was in 2021 that we found our rare pearl, which would bring Nissē lingerie to life. Located a few kilometers from Paris, our workshop perpetuates French corset-making know-how, an artistic profession that requires experience, technique and passion.

Three key elements had to be taken into account in the search for the workshop that would bring Nissē lingerie to life. Geographical proximity to Paris, to ensure local and environmentally friendly manufacturing, know-how, and human understanding with the teams. We are committed to being able to forge close ties with the women and men who are behind the development and manufacturing of our pieces.

Excellent corset-making know-how

From drawing to product design, our workshop benefits from the latest technologies in lingerie-corsetry, to ensure quality manufacturing. A workshop on a human scale and with strong values of excellence supported by its 60 experienced seamstresses. The seniority of our craftsmen is a guarantee of passion and quality: Sandrine, the quality operator, has 30 years of experience in lingerie-corsetry, the same observation for Jacqueline, the Design Office agent, 36 years for Marie-Claude, who takes care of the cutting operations.

A 10-step manufacturing process

No fewer than 10 steps make up our development and manufacturing process in which the expertise of our craftsmen is key. It is a process which can be long (between 6 to 18 months) and which is explained by the duty of precision and quality that we have set ourselves for the release of the Essentielle collection by Nissē.

Step 1: Co-creation

It all starts from a discussion, an intimate and privileged exchange with women to identify their desires and expectations in terms of lingerie. It is this proximity and this permanent contact with women that nourishes our creative process. From the choice of materials, through design and colors, each step is decided collectively with the Nissē community of women.

Step 2: Material sourcing

All materials come from European suppliers and are OKEO-TEX Standard 100 certified, an international label which guarantees the safety of the textiles used for people and the environment. Innovation for the well-being of women and the environment is at the heart of Nissē DNA. We constantly seek the best durable and high-performance materials , never compromising on style and desirability.

Step 2: The stylistic drawing

It is worked in collaboration with our model maker and the machine technician who helps in choosing the best finishes. It is from the technical drawing produced by a stylist that the workshop comes into play to develop the first patterns.

Step 3: Modeling

The pattern maker translates the stylistic drawing into a pattern. She is a technical expert, guaranteeing the fit and comfort of the product. His work is key to obtaining a perfect fit.

Step 4: Prototyping

From the pattern made by the pattern maker, it is the seamstresses in concert with the machine technician who come on stage: the materials are cut according to the pattern, the machines are adjusted and set, and it is the seamstresses who, with their invaluable experience, give life to the first parts: the prototypes.

Step 5: Focus

Time for fine-tuning through worn fittings. It is necessary to ensure that the prototype is faithful to the stylistic drawing AND that the product sizes correctly. If this is not the case, a second prototype is made. It can take between 3 to 5 back and forths before finding the perfect fit.

Step 6: The quality test

At the same time, the first prototypes are manhandled by machines to ensure the quality of the materials and the assembly carried out: no seam must crack, no stitch must jump and the material must remain intact.

Step 7: Dimming

Once the first prototype has been validated, it will be available in several sizes. A few sizes will be fitted to ensure a final fit.

Step 8: The Last Fit

Penultimate step, we ensure that the developed sizes perform well visually and when worn.

Step 9: Ok Prod!

“OK PROD!”, this sentence is the key that means that we can launch production. Which means that we have validated everything: both the visual aspect, the product comfort and the quality of the assemblies.

Through this carefully thought-out manufacturing process, from the choice of materials to the choice of workshop, including an exchange with women, Nissē embodies a vision of lingerie that is both innovative and contemporary, while remaining deeply attached to to the tradition and artisanal techniques of yesteryear.